The quality of the Precision Welding Wires is characterized by the use of steels with low content of impurities deriving from integrated cycle. This allows to obtain products granting high mechanical characteristic (tensile and impact values) even at low temperatures as well as a very good stability of arc and no spatters. During the production process, the wire rod is mechanically scaled and electrolytically pickled on a plant on line. After the drawing process the wire undergoes a powerful cleaning operation in order to guarantee a total absence of residual particles on the surface and therefore a perfect copper adherence. Systemmatic controls effected on the finished product before the packaging operation (verification of the physical, chemical and geometric properties) guarantee its perfect suitability.

Agglomerated flux made by PWL is a heterogeneous product where the individual powdered particles of the raw-material are bonded and baked together in their original and natural quality. That means: each grain of and agglomerated flux is heterogeneous but all these heterogeneous grains are identical among each other. Thus constant metallurgical reaction during welding and uniform welding characteristics with reproducible results can be obtained. It is worth making the point that PWL fluxes are baked at a higher manufacturing temperature (around 800°C). Together with the prebaked and selected raw-materials a low hydrogen potential is achieved withe PWL agglomerated fluxes

Being an ISO 9001 certified company, we strongly believe that quality control and assurance department is the backbone of every growing company. Our state-of-the art laboratory houses chemical, mechanical and welding labs equipped with Universal testing machine, impact testers, hardness tester etc. Company specific and standard procedures are followed to check and test each and every step of production from procurement of the raw materials to finished products. Special quality control stations are installed to test the quality of manufactured items, and each lot goes through these stringent tests.

Dehumidifier

Flux packing and loading

Lab

Loading of Welding Wire

Packing

SAW Wires and SAW Flux testing

Spool loading

Labaratory

MIG WIRE SPOOL

Plastic 15Kgs

Spool

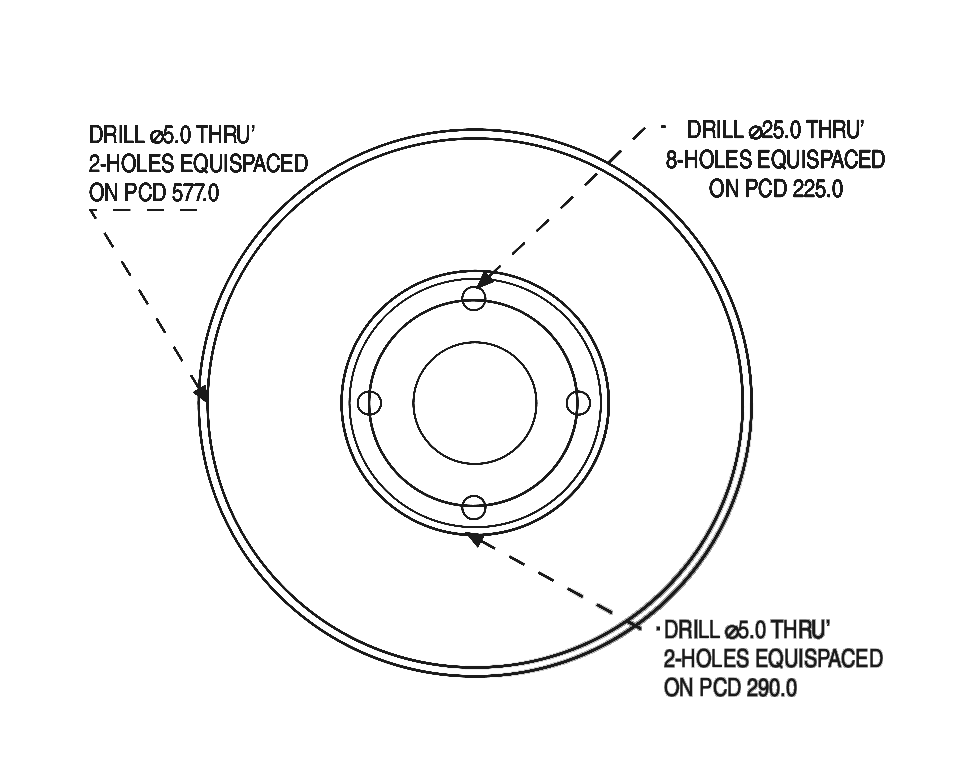

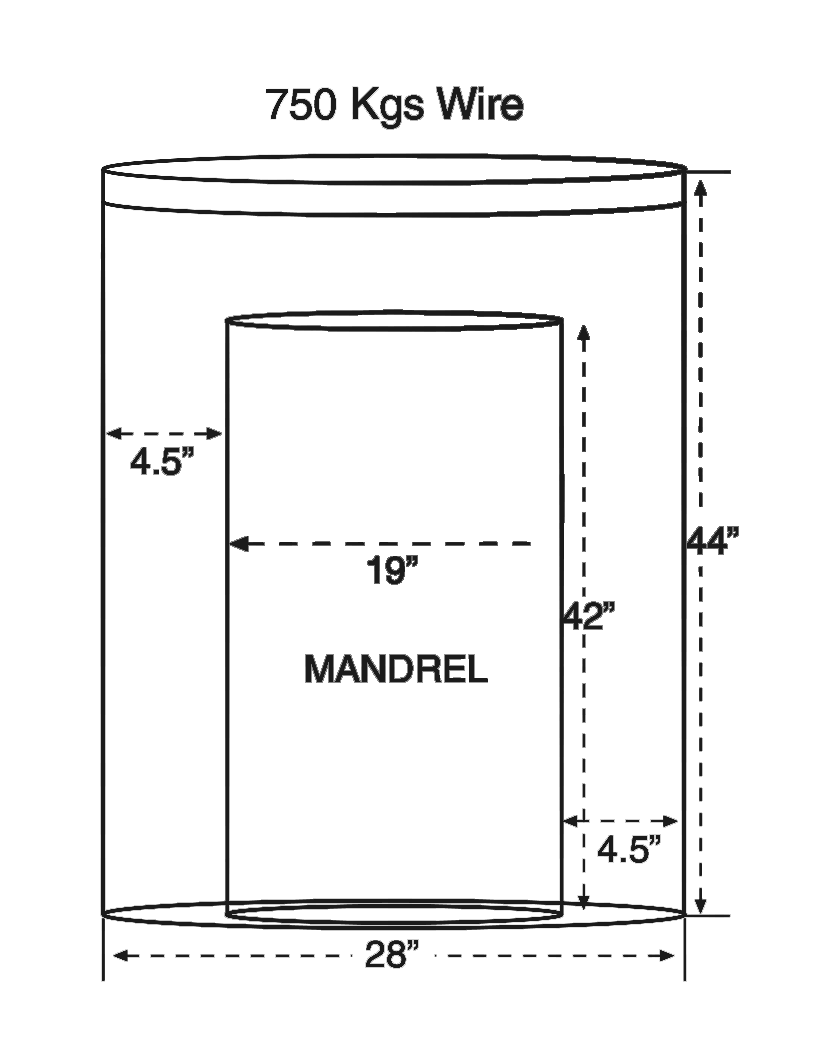

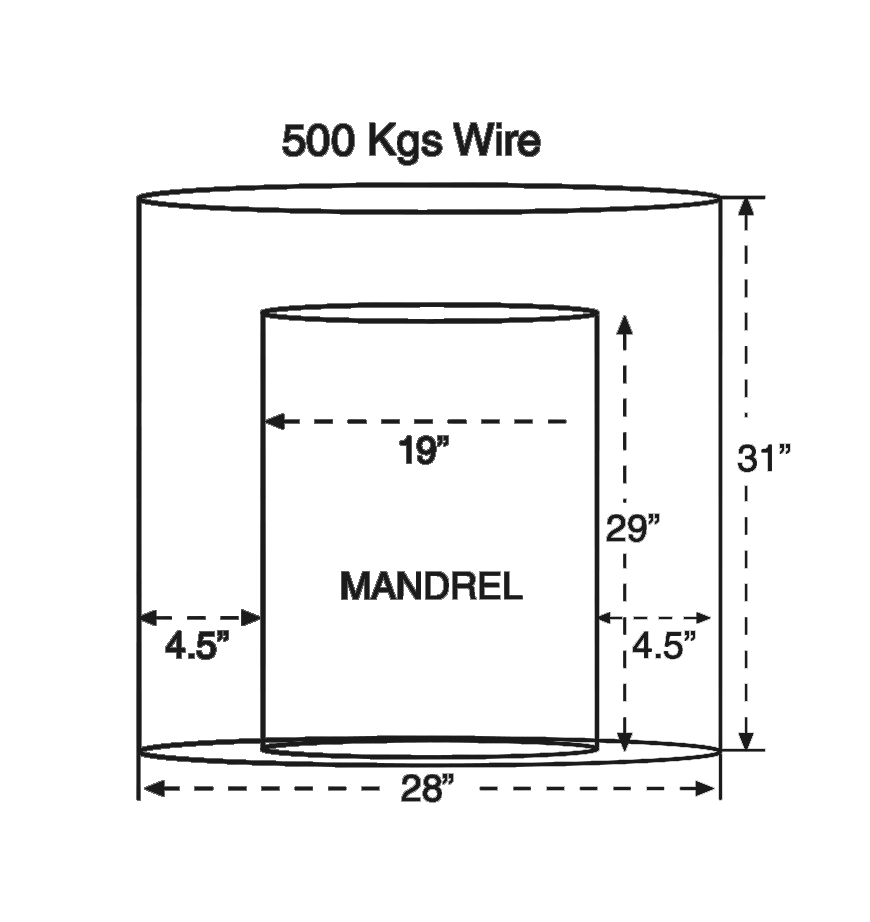

SAW WIRE SPOOL

Spool Weight : 20 - 30Kgs (depending on wire)

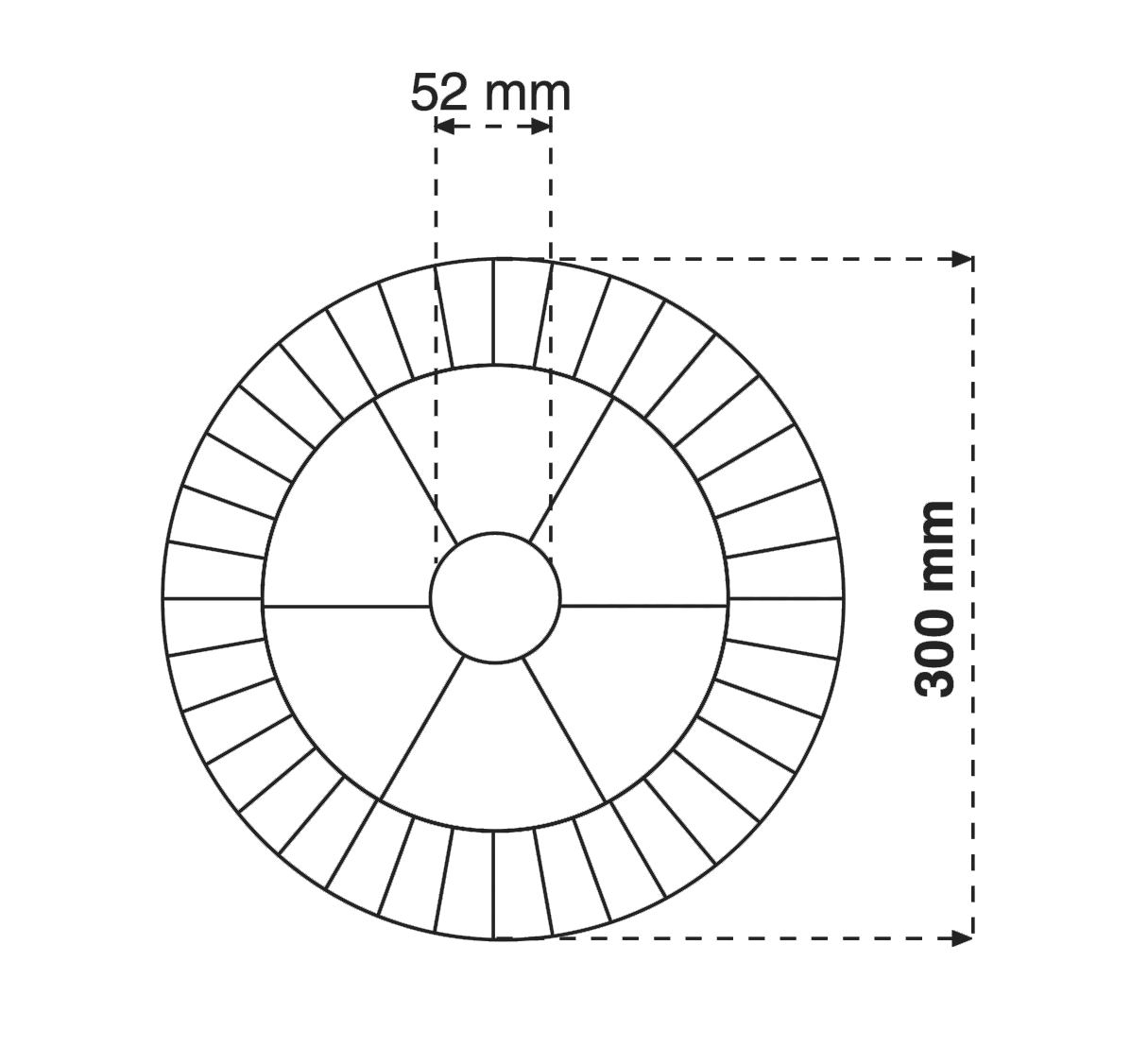

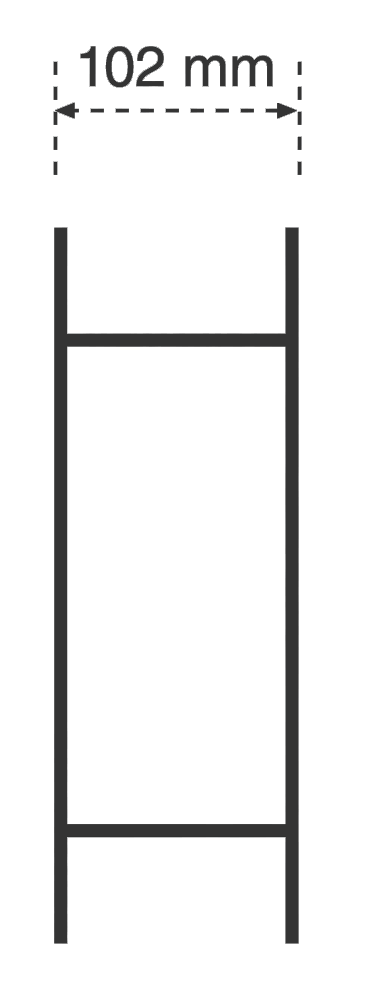

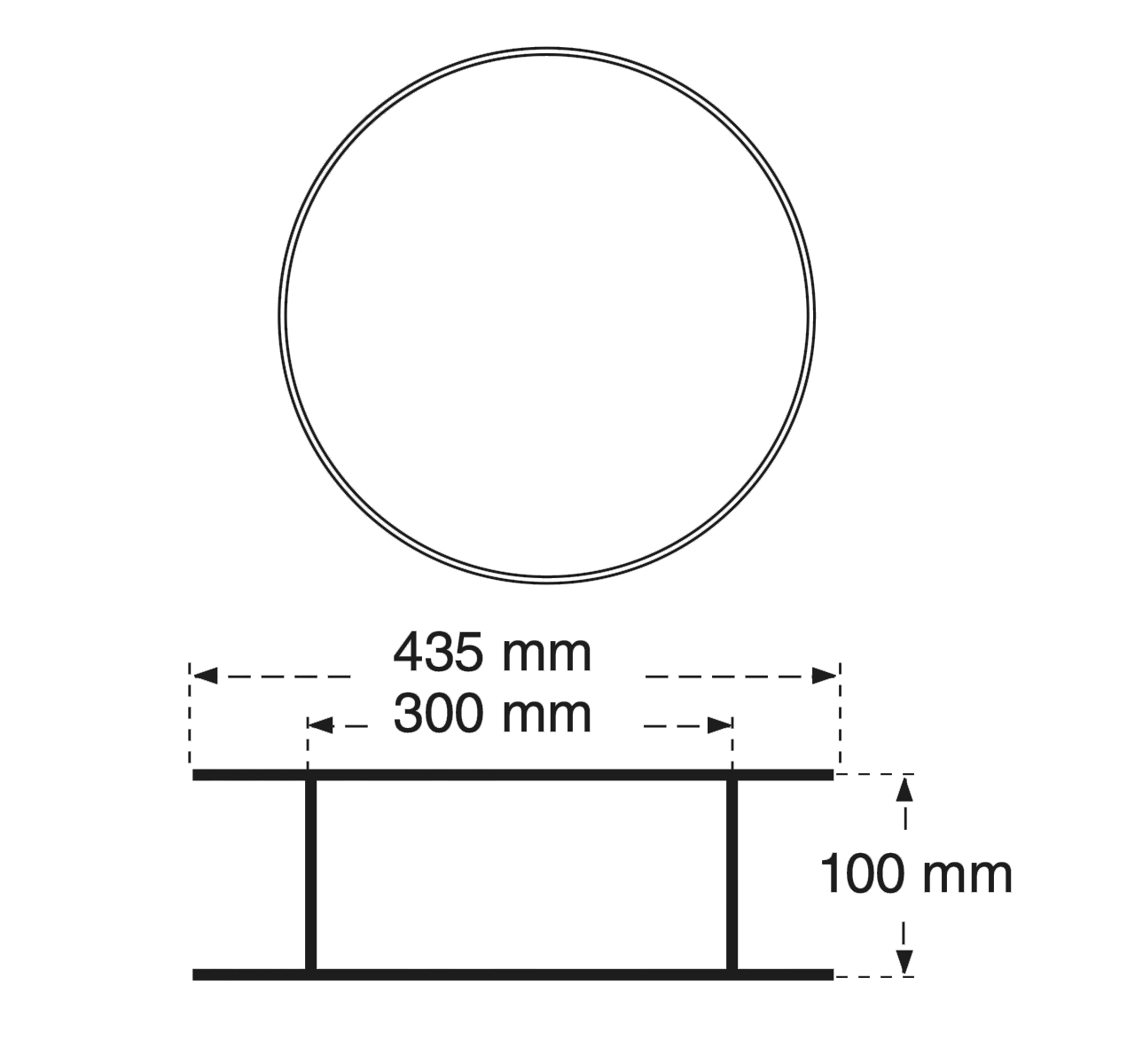

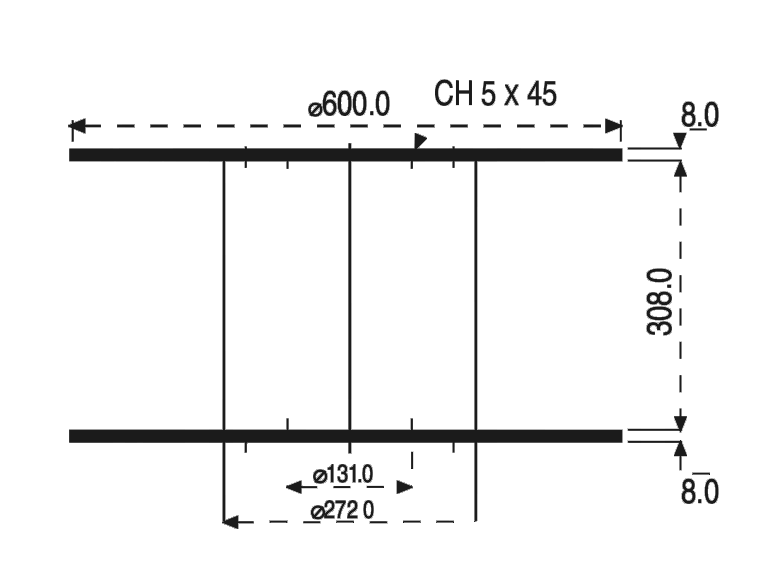

Coil/Spool Dimension of K 435

| Type | Outer [mm] | Inner [mm] | Width [mm] |

|---|---|---|---|

| K435 | 450 max | 300 + 5 | 100 + 3 |

Ring

Bobbin Packing

250 Kgs

Bobbin

Drum Packing

.jpg)

Drum

Before the final packaging of the product the product in a dehumidifier room equipped with latest dehumidifying machines to prevent moisture.